Pulp-Injection

Pulp-Injection at a glance

- Extensive design flexibility

- Precise, Thin, and Rigid as plastic

- Recyclable as paper*1

- Less water consumption

- Premium paper-like texture

*1 Local regulation needs to be checked.

We offer one stop solution from product design to mass production in Germany and Japan.

Material

Pulp-Injection pellet consist of mainly pulp, starch and small amount of water.

Thanks to the high pulp content (> 50%), the products are classified as non-corrugated fiberboard with PAP 21 recycling code and recyclable in existing paper recycling system.

-

Pulp -

Starch -

Pulp-Injection Material

Process

Pulp-Injection production process is not ‘Thermoforming’ but ‘Injection molding’. The combination of unique material composition and our process know-how makes unique product shape and properties.

-

- Material preparation

- Pulp-Injection pellet is moisturized to be injectable into a mold.

-

- Injection molding

- The material is injected into a mold and formed.

-

- Drying in mold cavities

- The water content is vaporized in the cavity.

-

- Post trimming

- Unnecessary part is trimmed out.

| Material preparation | Injection molding |

|---|---|

|

|

| Drying in mold | Trimming & Deflashing |

|

|

Process video

Recyclability and Bio-based content

-

Pulp-Injection is classified as ‘Non-corrugated fiberboard(paperboard)’ with PAP 21 recycling code in Europe.

The products are disintegrated well in repulping process and are recyclable in a common paper recycling system according to the test results following PTS-RH 021:2012. -

The biomass content level is 90%.

Biomass mark (90%) No.230137 certified by Japan Organics Recycling Association

Specifications

| Max. parts size(mm) | 300 × 300 × 50 | Parts thickness(mm) | 0.6 〜 1.0 |

|---|---|---|---|

| Minimum radius(mm) | 0.5 | Typical annual production volume(pcs) | 200,000 〜 |

Pulp-Injection properties in comparison to industrial-grade plastic

| Teststandard | Industrial plastics |  Pulp-Injection |

||

|---|---|---|---|---|

| Polystyyrene (PS) |

Polypropylene (PP) |

|||

| Specific gravity | 1.05 | 0.9 | 0.85 | |

| Impact strength(Mpa) | JIS K 7161 | 6 | 6.6 | 11.5 |

| Tensile strength(%) | JIS K 7161 | 28 | 19 | 29 |

| Strentchability(Mpa) | JIS K 7171 | 40 | 80 | 8.5 |

| Bendingstrength(Mpa) | JIS K 7171 | 47 | 33 | 24.5 |

| Bending elasticity(Kj/m2) | JIS K 7110 | 2,500 | 1,200 | 2,900 |

| JIS: Japanese Industrial Standards | ||||

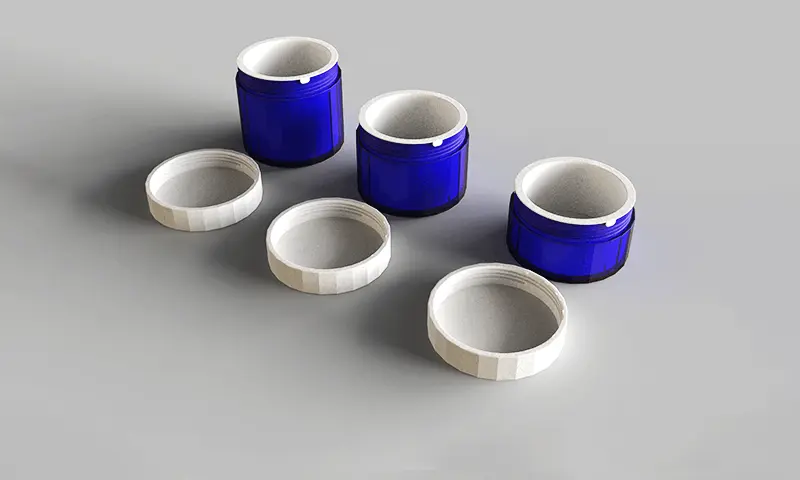

Application examples

-

Pharmaceutical

Self injector tray -

Ampoule tray -

Cap and Closure *Under development

-

Cap and components *Prototype available

-

Trays -

Refill cup *Under development

All products are custom-designed. Our sales team are happy to discuss with you about specific design requirements, quantity and sustainability challenges.