PaperFoam®

Foam Molded Products -

Lightweight and Cushioning

- Foam molding of pulp and starch

- Lightweight but high cushioning properties

- Securely fix products or components

- Lightweight compared to plastic

(specific gravity: approx. 0.2) - Extensive design freedom in shape achieved through molding process

- Various colors, textures, embossing options

- Recyclable as paper*

*It depends on the regulations and guidelines of each country or region.

Process

The main ingredients, starch and pulp, are mixed with water and injected into the mold.

Heat is applied simultaneously during molding to cause foaming and create a 3D shape.

At the same time, the moisture inside the material is evaporated, drying the product and completing the manufacturing process.

Key Features

-

Lightweight and Cushioning properties

PaperFoam® has excellent cushioning properties due to its foaming process. Additionally, its lightweight material properties (specific gravity is approx. 0.2) contribute to total weight reduction of packaging.

-

Securely fix products or components

Thanks to the molding process, PaperFoam® is capable of taking on a shape that perfectly fits to the product, providing a secure fit and effectively safeguarding it against shakings and vibrations during transportation.

-

Precise dimensional accuracy

It is possible to design an integrated tray by combining several packaging parts made of PaperFoam®, such as the lid and body, thanks to its precise dimensional accuracy.

-

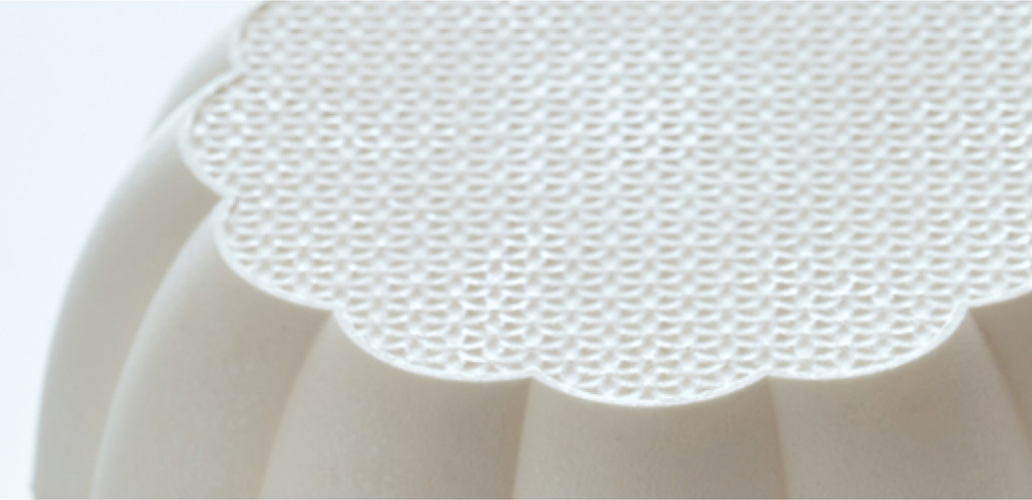

Customized textures and colors

Products can be colored, textured and embossed in a wide range of designs.

Application examples

-

Mobile battery

case -

Cosmetics

Set box inner tray -

CPG (Earplug)

Inner tray -

Toy Inner tray

Certification

- TUV Austria OK biobased (4 stars)

- TUV Austria OK compost Home & Industrial

- UL Validated: 99% recovery rate of available fibers

Specification

| Max. parts size(mm) | 200 × 300 × 150 | Parts thickness(mm) | 2.2 〜 3.0 |

|---|---|---|---|

| Minimum radius(mm) | 2.0 | Typical production volume (annually)(pcs) | 100,000 〜 |